Foggers for Aeroponics Systems

Welcome to our comprehensive guide on Aeroponics Systems and Micronice fogging and spraying Solutions. Explore how these innovative methods revolutionize agriculture by cultivating plants without soil, optimizing nutrient delivery through misting systems.

Discover the benefits, applications, and environmental advantages of these cutting-edge techniques in modern farming and urban agriculture and how Tekceleo can help you achieve it !

Efficient Technology for

Better Controlled Aeroponics Systems

Our MICRONICE© fogging nozzles make the most of their advantages to perpetuate the use of an aeroponic system:

- Gentle misting (no projection, monodisperse granulometry) and controlled misting (flow rate and granulometry adaptable and programmable via control software).

- Very low power consumption (2W/nozzle for battery operation).

- A modular fluidic system (each nozzle can be autonomous and replaced).

- A robust system that can operate continuously over a very long period (several years with tap water).

- Extremely quiet operation in enclosed work areas.

Our M50 (50 µm) vibrating mesh nebulizers are particularly well-suited to this application, as they can project micro-droplets in the 40 to 50 micron range – the optimum size for an ideal nutrient mist. The robustness of our nozzles also greatly reduces maintenance and the cost of ownership of the aeroponic fluidic system.

One of the Most Effective Growing Technique

Most research shows that aeroponics is one of the most effective agronomic techniques. The main factors explaining the effectiveness of aeroponics are as follows:

- Ease of nutrient absorption, enabling a 60% reduction in fertilizer inputs;

- Oxygen-rich root system, preventing fungal diseases;

- CO2 directly accessible to the roots, considerably accelerating their growth;

- Full health and natural defenses, as the plant is fed at will and, in a controlled environment, all its energy is devoted to producing leaves, flowers and fruit;

Aeroponics eliminates the need for pesticides, herbicides and algicides, while reducing the use of fertilizers. This precision farming technology therefore solves two problems currently encountered by conventional agriculture:

- Extensive and intensive soil use

- High Dependence on inputs (fertilizers, pesticides, etc.)

What is an Aeroponics System ?

Aeroponics cultivates plants in a misted environment devoid of soil, with roots suspended in air. Nutrient solution is sprayed onto roots, fostering rapid growth and high yields. This soilless method conserves water, maximizes nutrient absorption, and offers precise control over plant environment, ideal for space-constrained or urban farming.

As a result, Aeroponics is a highly efficient growing system that eliminates the need for growing substrates by cultivating without soil, and spraying water and nutrients directly onto the roots using a spraying or fogging technique. This requires a set up where the root system is in the open air, so that a nutrient solution can be sprayed onto the roots at regular intervals.

The advantages of this technique are manifold: it removes any obstacle to root propagation, provides better control over nutrient supply, and prevents the development of diseases and parasites, which are mainly present in the soil.

Secret Behind our Humidification Nozzle

Our Amplified Vibrating Mesh Technology use a piezoelectric transducer to make a micro-perforated mesh (membrane) vibrates at ultrasonic frequency. Whenever a liquid (solution, formulation, suspension) is in contact with the vibrating membrane, it is “extruded” into a cloud of micro-droplets on the other side of the membrane through micro-perforations.

As a matter of physics, the aerosol or spray is not generated by any pressure inside the nebulizer nozzle. As a result, our technology does not use any violent or restraining physical property to create a fog, making it very compact, robust and energy efficient !

Most Resources Efficient Technology

Efficiency is what sets our technology apart. Micronice vibrating mesh technology is unique and has the best efficiency to size ratio, with great volume, an energy efficiency that is better than a LED lighting and a very low water consumption.

If we compare a system using Micronice technology to a system using ultrasonic fogging or usual misting technology :

- It uses 60% less water than a standard misting system

- It uses 12Wh/L compared to 250Wh/L for an ultrasonic unit

- Its long lifespan means less need to replace part

- Small footprint of the nozzle and system, as well as direct nebulization, which means less parts, less installation time and less risk of breakage and/or contamination. For example, our technology does not need any blower or complex control system.

As a result, choosing Micronice vibrating mesh technology for your humidification systems is the best resources-efficient choice you can make. Which means a better use of resources and less operational expenses during the life of the product.

If you want to use our technology and start an integration process, do not hesitate to contact us ! We provide a free engineering support.

How to Implement Micronice for Aeroponics Systems ?

Micronice technology can be implemented in various application, it is well suited for working spaces (quiet operation), but also for complex volume humidification or spraying/fogging of the roots sytem of the plants.

In order to integrate our technology in your solution and adapt it to your use case, the main elements you need to take into account are :

- Clarify your use case : humidity control or spray to the roots ?

- Define the liquid used and volume of liquid you need to spray

- Define the surface and air volume you need to spray into

- Design your work environment : volume, place for the plants, flowrate, airflow

- Place Micronice Nozzles in your volume, following :

- Dimensioning study

- How many nozzles you’ll need

- Adapt fluidic system : pressure loss, pump’s dimensioning, etc.

- Build your control unit : interface the electronic controller to your own PLC

- Plug all components together and define your duty cycles

Developping your Own Controlled Environment

Traditional centralized misting systems (ultrasonic, high-pressure or pneumatic) require substantial investment and maintenance downtime, and are noisy and inflexible. What’s more, nozzles need to be replaced every 2 weeks to 2 months.

Our technology is natively computer-controllable (Electronic Nebulization) and does not require complex valve systems and pressure generators (hydraulic or pneumatic) to operate. What’s more, because our technology is based on a piezoelectric vibrating membrane, it works ideally with mineral-rich formulations, provided these are water-soluble.

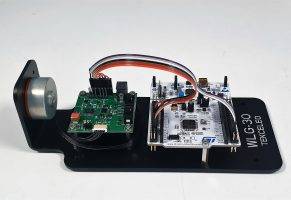

Micronice’s is a modular technology, allowing to easily adapt it to any configuration you may need. In our technology, nozzle is a compact active parts that only needs a simple fluidic system and power supply. With a very small footprint for all components (20mm diameter for the nozzle, control system fits in half a shoebox), it is perfect for space-constrained environments such as aeroponics farms.

Benefits from Tekceleo’s Engineering Support

As a modular technology, it is necessary to adapt it to our own use case and systems, which is easy with Tekceleo’s support and resources. We help you in every step of your project, from early stage development though the first prototypes to industrial scale.

Our team of engineers can support you at every stage in the design and industrialization of your aeroponics system:

- Characterization of your nutrient liquid

- Assistance in integrating our bus/controller pair into your aeroponic system

- Responsive technical support

Feel free to contact us so that we can discuss your project !

Our Articles

As 2024 draws to a close, we at Tekceleo reflect on a year filled with meaningful achievements, innovation, and global outreach. Here are some of the highlights that defined our year: Global Presence: Showcasing Innovation at Leading Trade Fairs MEDICA…

Tekceleo is pleased to announce the renewal of its ISO 9001 certificate for another three year certificate. Indeed, 2024 was the year of the complete audit of our quality management system, and we have succeeded in obtaining ISO 9001 certification…

Tekceleo and Virexpr, have joined hands to improve research and development on contamination through aerosol and bioaerosol behaviors. As a reliable supplier, Tekceleo provided its unique aerosol generation technology to Virexpr to generate atmospheres contaminated with infectious viruses and other…

This blog post is about a groundbreaking development by researchers at UC Berkeley, featuring Tekceleo's ultrasonic motors (USMs), set to redefine the possibilities for MRI-guided surgical robots.

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…