Pharmaceutical

Spray Drying

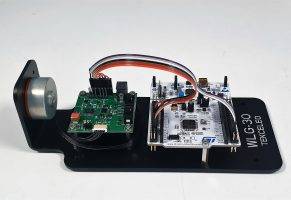

In pharmaceutical manufacturing, simplicity often translates to efficiency. Tekceleo understands this principle well, and we’ve made pharmaceutical spray drying easier than ever with the Micronice Aerosol Generator.

Whether you’re working with active pharmaceutical ingredients (APIs), excipients, or other crucial components, our technology simplifies the spray drying process, delivering outstanding results with minimal complexity.

Pharmaceutical Spray Drying Made Easy

Streamlined Operation

Imagine a pharmaceutical spray drying aerosol generation decive that is intuitive and user-friendly. Micronice’s design achieves just that. With its straightforward operation, you can reduce the learning curve for your team, ultimately saving valuable time and resources.

Enhanced Efficiency

Efficiency is at the core of Micronice’s design. It optimizes your spray drying processes on the aerosol generation process, allowing you to produce pharmaceutical powders and particles more quickly and effectively. This boost in efficiency not only accelerates production but also leads to cost savings over time.

Dive into our Amplified Vibrating Mesh

Electronic Sprayer Range

The Fundamental of Spray Drying

Before we dive deeper into the advanced features of Micronice, let’s explore the fundamental principles of spray drying. This foundational knowledge is essential for understanding how our technology enhances pharmaceutical spray drying.

At its core, spray drying involves the atomization of a liquid substance into tiny droplets, which are then rapidly dried using airflow (hot or at very low temperature). This process transforms the liquid into dried particles or powders, ready for various pharmaceutical applications.

For instance, in the formulation of inhalable dry powder medications, the active pharmaceutical ingredient (API) is often combined with excipients and then spray-dried. The resulting fine particles allow for precise drug delivery to the lungs, making it an effective treatment for respiratory conditions like asthma.

Gentle and Precise Spraying Method

Our spraying method is engineered to handle organic solvents gently and precisely. It guarantees uniform dispersion of these solvents, minimizing the risk of unwanted chemical reactions. This level of precision and safety is crucial, especially when working with sensitive drug compounds.

Electronic and Flexible Control of Spray

Micronice’s electronic spray control offers unparalleled flexibility. It allows you to precisely adjust key parameters such as spray rate and droplet size, ensuring optimal results while adhering to the highest safety standards when handling organic solvents.

Technical Details

For instance, the electronic control system enables you to modulate the spray rate of the organic solvent, ensuring it matches the evaporation rate, thereby preventing over-saturation or uneven drying. This level of control is essential for achieving the desired particle size and distribution in the final pharmaceutical product.

Spraying Method for Safe Organic Solvent Handling

In pharmaceutical manufacturing, particularly when dealing with certain formulations, the safe handling of organic solvents is paramount. Micronice introduces a spraying method that ensures the controlled and secure use of organic solvents, reducing risks while maintaining exceptional precision and efficiency.

Micronice technology does not use any diluting gas, any heating or pressure in its process. The process is very gentle, with very low energy consumption (<1,5 W), thus saving all the important property of the API and avoiding any risk of external contamination.

Our technology also ensure a monodispersed distribution of droplet sizes generated, which is great for repeatability and quality of the powdered API generated in the spray drying process.

Time Saving and Flexible Spray Method

In pharmaceutical manufacturing, time is often a critical factor. Micronice’s efficient spray method not only saves valuable time but also offers flexibility that adapts to a variety of pharmaceutical formulations.

Micronice’s efficient spraying process significantly reduces the time required in the spray method in your spray drying equipment. This time-saving feature accelerates production timelines, allowing pharmaceutical manufacturers to meet market demands promptly.

Pharmaceutical formulations vary widely in their characteristics. Micronice’s flexible spray method can adapt to these variations. Whether you’re working with APIs, excipients, or complex formulations, our technology ensures consistent and reliable results.

High Reproducibility of Aerosol Generation

Micronice’s advanced technology guarantees high reproducibility in aerosol generation. This means that batch-to-batch variability is minimized, ensuring consistent product quality and simplifying the regulatory compliance process.

Technical Details

In practice, this high reproducibility translates to the consistent production of pharmaceutical powders with precisely controlled particle sizes and distributions. Whether you’re manufacturing inhalable dry powder medications or creating oral solid dosage forms, Micronice ensures that each batch meets the same stringent quality standards.

Precision Redefined - Microvolume Spraying

In the pharmaceutical world, precision is everything. Micronice takes precision to a whole new level with its microvolume spraying capability. This level of accuracy empowers pharmaceutical manufacturers to achieve uniform particle sizes and controlled drug delivery, pushing the boundaries of pharmaceutical innovation.

Micronice for Reproducible Spray Drying Aerosol

Micronice’s advanced technology guarantees high reproducibility in aerosol generation. This means that batch-to-batch variability is minimized, ensuring consistent product quality and simplifying the regulatory compliance process.

Our technology allows customized droplet size and range of precision. By easily changing key parameters of the vibrating mesh our customer can reach accuracy of spray up to 1 µL/min.

Example

Imagine a pharmaceutical company developing a dry powder inhaler (DPI) for the treatment of respiratory diseases. With Micronice’s microvolume spraying, they can precisely control the particle size of the DPI formulation, ensuring optimal deposition in the lungs and maximizing therapeutic effectiveness.

Empowering the Pharma Industry

Tekceleo’s Micronice Aerosol Generator redefines pharmaceutical spray drying, making it easy, safe, and highly efficient. With streamlined operation, enhanced efficiency, controlled organic solvent handling, time-saving advantages, and exceptional reproducibility, Micronice empowers pharmaceutical manufacturers to achieve the highest standards of quality and performance in spray drying processes.

Our Articles

As 2024 draws to a close, we at Tekceleo reflect on a year filled with meaningful achievements, innovation, and global outreach. Here are some of the highlights that defined our year: Global Presence: Showcasing Innovation at Leading Trade Fairs MEDICA…

Tekceleo is pleased to announce the renewal of its ISO 9001 certificate for another three year certificate. Indeed, 2024 was the year of the complete audit of our quality management system, and we have succeeded in obtaining ISO 9001 certification…

Tekceleo and Virexpr, have joined hands to improve research and development on contamination through aerosol and bioaerosol behaviors. As a reliable supplier, Tekceleo provided its unique aerosol generation technology to Virexpr to generate atmospheres contaminated with infectious viruses and other…

This blog post is about a groundbreaking development by researchers at UC Berkeley, featuring Tekceleo's ultrasonic motors (USMs), set to redefine the possibilities for MRI-guided surgical robots.

This blog post focus on the research of Oveis Pourmehran one Tekceleo’s partner, who uses Micronice nebulizers for his medical research at University of Adelaide, more specifically on Chronic Rhinosinusitis.Its research was focused on how to solve a modern a…

Abstract: 25W performance ultrasonic motor to open new field of application This article presents a groundbreaking development in ultrasonic motor technology: the design and performance analysis of a new 75 mm diameter non-magnetic travelling wave ultrasonic motor capable of delivering…

Introduction: Tackling the Global Burden of Cardiovascular Diseases Cardiovascular diseases, accounting for an alarming 32% of global deaths, necessitate innovative solutions for efficient diagnosis and treatment. In this comprehensive exploration, we delve into the pioneering research from University College London…

In the landscape of rotary motors, engineers often find themselves at a crossroads when selecting the optimal technology for their applications. In this article, we will conduct a focused comparison between two distinctive categories within two main technology available: Piezoelectric…

In an ongoing commitment to innovation and customer satisfaction, Tekceleo is proud to announce the release of its latest software update for the Micronice HMI (Human Machine Interface). This new update brings significant improvements to the HMI's functionality, empowering users…

In various industries such as healthcare, pharmaceuticals, food processing, and research facilities, maintaining a sterile and safe environment is of utmost importance. Traditional decontamination methods often involve manual labor, complex procedures, and potential risks to personnel. However, with the revolutionary…